Substrates

Metalized Substrates

Aegis Technology has developed proprietary processes for the metallization of ceramic substrates including Si3N4, Al2O3, AlN and BeO. In addition, the company has also developed processes for the metallization of graphite based materials including diamond and C-C composites. These metalized substrates are used for power electronics, microwave and RF devices, amplifiers, laser diode arrays, and photo-detectors. Typical metalized substrates include direct bond copper (DBC) on ceramics for use in power electronics and direct bond Molybdenum for other high temperature electronics.

Custom metallization and thicknesses are available upon request.

MMC Insulated Substrate

Aegis Technology has developed a world-leading metal insulated substrate. This metal insulated substrate is based on a AlN coating on Al-based metal matrix composite (MMC). This metal insulated substrate integrates both a ceramic with a MMC base plate. Such metal insulated substrates can be scaled to large dimensions and can be used as part of a printed circuit board. In addition, such substrates have high thermal conductivity and low CTE (coefficient of thermal expansion). For example, the thermal conductivity of Al-based MMCs is 120-180 W/mk and has a CTE of 9.0-16.0 x 10-6 /K. These substrates are compatible with Si, GaAs, SiC, and GaN devices. In addition, these substrates are suitable for high heat flux.

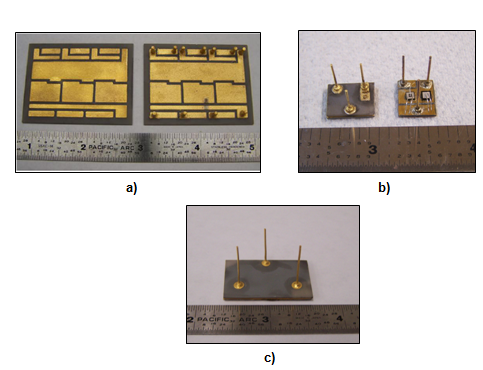

a) AlN substrate with Cu-Ag metallization and Kovar pins

b) Comparison of PPDAB packages to conventional Al-wire bonding

c) PPDAB process used for packaging Si IGBT and freewheel diode